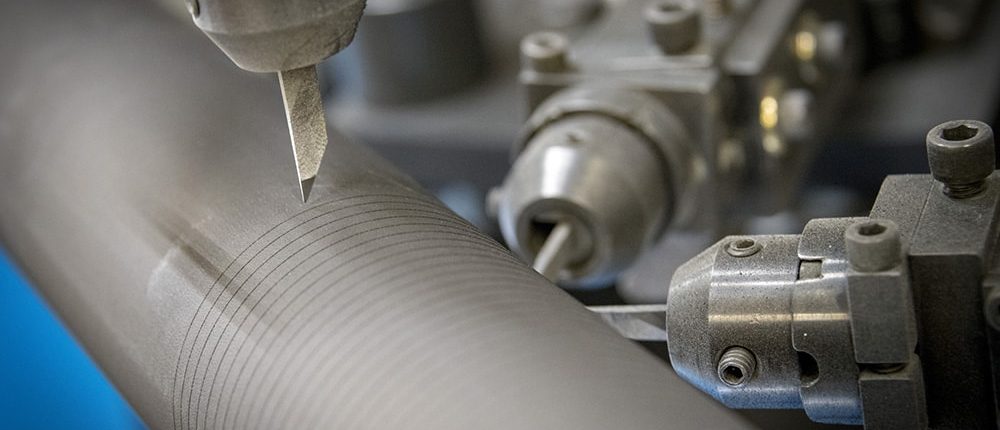

When to Choose a Lathe-Cut Gasket

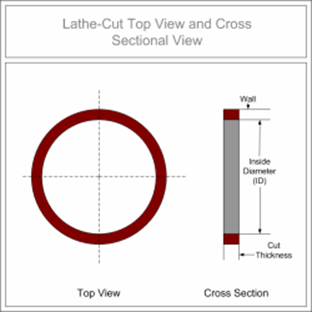

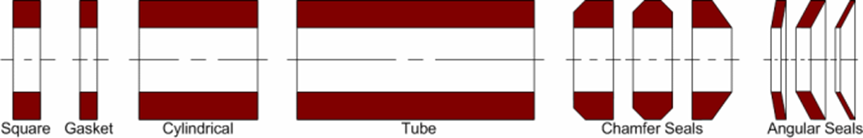

Lathe-cut gaskets are the optimal choice for static applications, meaning applications including immovable parts. Its rectangular or square cross-section offers a larger sealing surface. It also provides increased resistance to compression when compared to O-rings. Lathe-cut gaskets are ideal when beveled edge gaskets or tight tolerance gaskets are required. Also, the lathe-cutting process is optimal when large outside dimension (OD) gaskets or small ID gaskets are necessary because of availability and cost.

Applications

- Water Meters

- Fuel

- Couplings

- Appliances

- Plumbing

- Industrial

- Dairy

- Chopper cots

- Auto Aftermarket

- Belts

- Filters

- …and many more!

Quality Lathe-Cut Gaskets Are Our #1 Value

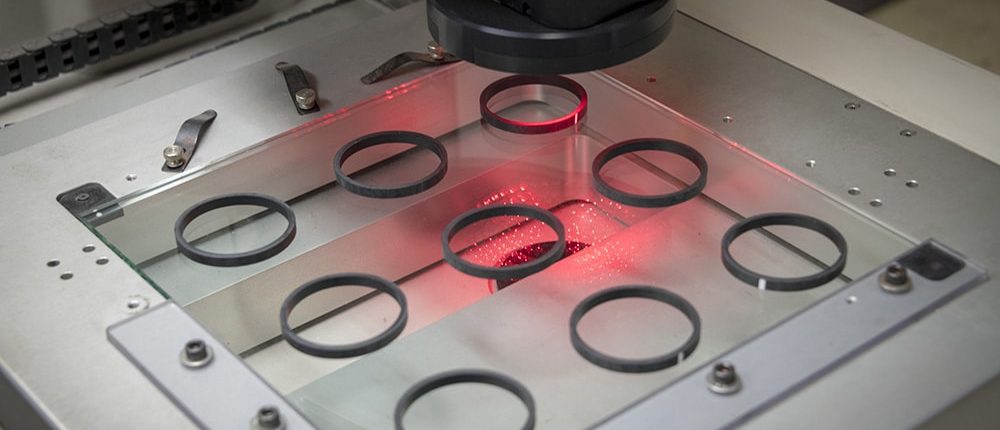

Grand River Rubber & Plastics utilizes a Statistical Process Control (SPC) program called Infinity QS throughout the lathe cut process. The program allows our staff to measure the wall thickness to the specification and also is used in the finishing step of our process to measure the cut size of the gaskets.

Grand River also utilizes a Microview Units Vision System that integrates with our SPC program. This unique program can measure Internal diameter (ID), outside diameter (OD), and wall thickness, all documented in our capability reports. This integral quality system can measure down to one ten thousandths of an inch.

Our customers approve production designs and processes before, during, and after manufacture. We use a Production Part Approval Process (PPAP) to communicate at each of these critical steps as we manufacture to your exact specifications. And, our lot-control system ensures full traceability from raw materials to final inspection. Through continuous quality improvement we can respond with innovative refinements to produce superior products.

Grand River Rubber Quality Certifications

Grand River uses a continuous improvement process from production to safety. We maintain the latest certifications and trainings, providing our customers with great quality.

- ISO 9001-2015 certified

- Recognized on the Interstate Milk Shippers (IMS) Certified Manufacturers List of Single Service Products

- NSF/ANSI Standard 61 Drinking Water Systems Certified Lathe Cut Gaskets

Value Add Options for Lathe-Cut Gaskets

We also offer a variety of value-added services such as packaging, bagging, labeling, and material review.

Packaging

We offer many different packaging options including core, stacked, and bulk packaging. Our team is happy to assist you in choosing the best packaging option for your project.

Bagging and Labeling

Grand River offers many bagging and labeling options. Parts can be bagged and tagged into specific quantities and labeled with P/N or any required information. We also have the ability to direct print labels or if you’d rather, send us labels to use during the bagging process.

Material Review

Our experts can help you determine the material that will work best for your application. Read “How to Choose Lathe Cut Gasket Materials for Various Applications” to learn more about the materials we recommend for specific applications.

ISO Certification

Grand River is ISO 9001:2015 certified in an effort to reduce unnecessary costs and guarantee the quality of our processes and products. We provide traceability on our gasket seals from the time a part is quoted up until the day it ships.

Lubricant Coatings and Special Performance Coatings

Many of our clients require lubricants and coatings for specific performance. We offer various coatings such as Talc and Silicon. We also offer Special Performance Coatings ( PTFE) which is not only great for identification (since it’s offered in different colors) but also is a great low friction/non-stick coating.